This morning (after our 2nd Covid19 vaccine shot) Susan and I took a trip to Biltmore Metal Recycling looking for steel and inspiration. You can never tell what you will find. We found some really cool things that were way bigger than we could move. Oh well.

This morning (after our 2nd Covid19 vaccine shot) Susan and I took a trip to Biltmore Metal Recycling looking for steel and inspiration. You can never tell what you will find. We found some really cool things that were way bigger than we could move. Oh well.

This project was supported by the North Carolina Arts Council, a division of the Department of Natural and Cultural Resources.

This project was supported by the North Carolina Arts Council, a division of the Department of Natural and Cultural Resources.

The interlocking vertical circles could be expanded as either a geometric series of shapes or it can be enhanced with additional organic elements. I have decided to move in the organic direction. An organic center “stalk and pod” should help balance the geometric quality. The question is how to design and make the center stalk/pod. I am planning on it to be made up of a steel, stainless steel, glass and cedar. Bending and cutting stainless steel for leaves will be the first step. The next hurdle is how to assemble the stalk, leaves and pod.

The interlocking vertical circles could be expanded as either a geometric series of shapes or it can be enhanced with additional organic elements. I have decided to move in the organic direction. An organic center “stalk and pod” should help balance the geometric quality. The question is how to design and make the center stalk/pod. I am planning on it to be made up of a steel, stainless steel, glass and cedar. Bending and cutting stainless steel for leaves will be the first step. The next hurdle is how to assemble the stalk, leaves and pod. The original idea for the base is done. This is the real sculpture from the SketchUp design. It was OK. The shapes were interesting, the size was right. It was not the complete design. The SketchUp design did not include the mast that was in the original maquette. I had the base standing vertically as I was working with finish welding. I really liked the way it looked standing on edge. So I made another one to interlock with it.

The original idea for the base is done. This is the real sculpture from the SketchUp design. It was OK. The shapes were interesting, the size was right. It was not the complete design. The SketchUp design did not include the mast that was in the original maquette. I had the base standing vertically as I was working with finish welding. I really liked the way it looked standing on edge. So I made another one to interlock with it.

Here is the full sized upright circle, inside and outside. There are some adjustments to be made to the cross connections. I am thinking about putting some stainless steel sheets inside of the two circles for a change in texture and reflectivity. Then it is on to the horizontal open circle that will form a section of the base (see the SketchUp model blog) . I want you to realize as you look at the blog series about this sculpture that the camera adds 60lbs to my images. Not only an I thinner, but I am taller as well. And more handsome, the camera does something about that as well. For some reason, the sculpture’s proportions seem to not be effected by this. Go figure.

Here is the full sized upright circle, inside and outside. There are some adjustments to be made to the cross connections. I am thinking about putting some stainless steel sheets inside of the two circles for a change in texture and reflectivity. Then it is on to the horizontal open circle that will form a section of the base (see the SketchUp model blog) . I want you to realize as you look at the blog series about this sculpture that the camera adds 60lbs to my images. Not only an I thinner, but I am taller as well. And more handsome, the camera does something about that as well. For some reason, the sculpture’s proportions seem to not be effected by this. Go figure. Ain’t it always da truth. To build something, you have to make something first. I needed a way to spread the steel apart in a controlled manner to weld up the sculpture. Something that would spread the rebar circle in small increments and keep it apart without having to hold it by hand. So, I went to my trusted source YouTube and input “spreader”. Well, I got a lot of manure spreaders, but I got this idea too. It was from something completely unrelated, but was “mucho inspirational”. Now I need a clamp that works like the spreader only in reverse. Maybe I’ll look in YouTube and find a manure picker upper. Oh, well. Onward and well, onward.

Ain’t it always da truth. To build something, you have to make something first. I needed a way to spread the steel apart in a controlled manner to weld up the sculpture. Something that would spread the rebar circle in small increments and keep it apart without having to hold it by hand. So, I went to my trusted source YouTube and input “spreader”. Well, I got a lot of manure spreaders, but I got this idea too. It was from something completely unrelated, but was “mucho inspirational”. Now I need a clamp that works like the spreader only in reverse. Maybe I’ll look in YouTube and find a manure picker upper. Oh, well. Onward and well, onward. The outside upright ring is done, I think. I may add some diagonal cross pieces for stability and looks. Now comes the inner ring for the upright piece. With all of the problems with getting the outer ring done, I thought “why not stop here.” I might be getting lazy in my old age, but no, it needs an inner ring. Oh well, tomorrow is another day. If it doesn’t rain. Rain is a big problem. My welding yard sometimes floods. Very problematic when using high voltage welding equipment. Here’s to no rain. You will note that I am not wearing my favorite work hoody. It caught fire while I was using an angle grinder. I thought something smelled funny and looked down and my hoody was on fire. Oh well, its warming up anyway.

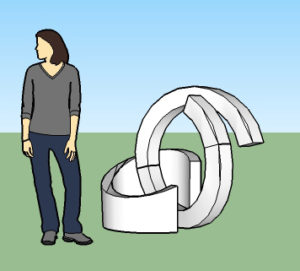

The outside upright ring is done, I think. I may add some diagonal cross pieces for stability and looks. Now comes the inner ring for the upright piece. With all of the problems with getting the outer ring done, I thought “why not stop here.” I might be getting lazy in my old age, but no, it needs an inner ring. Oh well, tomorrow is another day. If it doesn’t rain. Rain is a big problem. My welding yard sometimes floods. Very problematic when using high voltage welding equipment. Here’s to no rain. You will note that I am not wearing my favorite work hoody. It caught fire while I was using an angle grinder. I thought something smelled funny and looked down and my hoody was on fire. Oh well, its warming up anyway. Here is a SketchUp model of my sculpture. The person gives a idea of its size. There will be a “mast” that comes from the back of the sculpture and goes up on an angle through the split in the upright circle. I haven’t finished designing the mast yet. The mast should be about 10 feet long.

Here is a SketchUp model of my sculpture. The person gives a idea of its size. There will be a “mast” that comes from the back of the sculpture and goes up on an angle through the split in the upright circle. I haven’t finished designing the mast yet. The mast should be about 10 feet long.

Finally, I got to bend some rings. After a few tweaks, the ring roller works like it was designed to. I am beginning to lay out the sculpture. Bending the rings to just the right diameter was difficult at first. But after the first two, it worked its self out. Remember when you took Geometry in high school and said, “When am I ever going to use this?”. Well I have used it all through my life and especially in this sculpture. No geometry, no sculpture. I had a great geometry teacher that I would like to thank if I could only remember her name.

Finally, I got to bend some rings. After a few tweaks, the ring roller works like it was designed to. I am beginning to lay out the sculpture. Bending the rings to just the right diameter was difficult at first. But after the first two, it worked its self out. Remember when you took Geometry in high school and said, “When am I ever going to use this?”. Well I have used it all through my life and especially in this sculpture. No geometry, no sculpture. I had a great geometry teacher that I would like to thank if I could only remember her name.

The first iteration of the ring worked, but needed tweaking. I needed to fabricate some additional parts. Old exercise machine to the rescue. This is probably the most use this machine has seen. Lots of cutting and grinding. Lots of whacking. I’m heck at whacking. (see the Harrison Ford film Witness)

The first iteration of the ring worked, but needed tweaking. I needed to fabricate some additional parts. Old exercise machine to the rescue. This is probably the most use this machine has seen. Lots of cutting and grinding. Lots of whacking. I’m heck at whacking. (see the Harrison Ford film Witness)