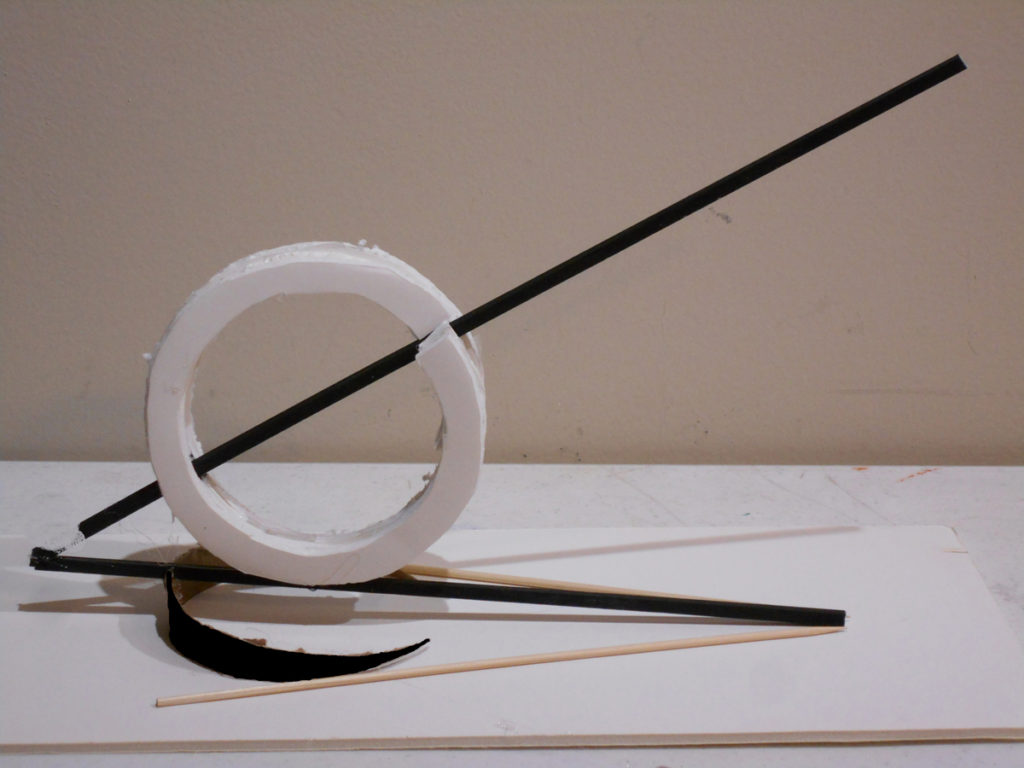

What would the sculpture look like squared off rather than round? Also it snowed and got very cold, so I thought why not work inside where it was warm. Susan said,”Let’s play paper dolls.” Foam core, balsa wood and a glue gun later… But, I think I like the round version better. The square one might work if I just used the upright part and made it much bigger. Maybe for a later project or a commission. I am trying out various ideas for a public sculpture. My first idea was to make a maquette that was about 6 feet tall by 6 feet long by 4 feet deep. Susan thought this was way, way to big for a maquette. This would make the finished sculpture more like 10 feet tall by 10 feet long by 5 feet deep. If I build it in my welding yard, it has to be able to be broken down into components to move. Like building a boat in your basement. So. We were having snowy and very cold weather and spent Monday January 11, 2021 inside working much much smaller. Balsa wood, foam core, bamboo skewers, hot glue. Smaller is harder to make. It lacks details and tends to fall apart. Better success Tuesday. Got rid of some ideas. Let me say here that bases are hard. How do integrate it with the sculpture and have it support the the weight and balance. Above is a very basic first shot. The finished piece will be some where between the first two sizes. I think I will stop here I am rambling. Ramble on. The biggest part of my grant was to cover the cost of a multi-process welder that would allow me to cut and weld larger steel for a public type sculpture. I did a lot of research and decided on one from PrimeWeld (due to the reviews about their customer service and a 3 year warranty). I ordered my PrimeWeld CT520D multi-process welder from PrimeWeld on December 13, 2020. Received my welder 12/16/2020. (See box opening and assembly below in previous post.) Then it rained. Then it snowed. Then it got really cold. Thank you, thank you, thank you, North Carolina Arts Council and Haywood County Arts Council for awarding me one of the Artist Support Grants. It will expand my artistic reach to larger works. Two years ago a similar grant got me on the road to sculpture. Few Americans visit art museums or galleries, even fewer own or consider buying art. They might see photos of art, but not the “real thing”. The only art most Americans interact with is public art. My project is to create a public art sculpture. The funds will be used to purchase a multi-process welder/plasma cutter, necessary electrical power upgrades, supplies and materials. The goal of the project is to experiment with juxtaposition. I will be exploring the contrast of balance and asymmetry, by employing contrasting surfaces, reflectiveness, and textures. I told my sister I got a grant to do a public sculpture. She asked some questions: All good questions. I said: None of these things are really important. If it was a commission, it should fit with the environment. Since it is right now just for me and mine, I can make it anyway I want. Oh Boy. Now what! Here is a piece I sold in 2019 that I may use as an inspiration. Different size, different materials, different base. You know an inspiration, not just a bigger copy.

Latest clock. A friend was cleaning out her barn and brought me a pile of rough cut lumber. There was some walnut and oak. The oak was thin, so I had to be creative with how to use it. I used it for the layered face and highlights/inlays. The walnut for the “legs” was slightly warped. Taking a lesson from Bill Gates, it became a feature not a bug.Deluxe Tube Ring Roller almost completed

The first iteration of the ring worked, but needed tweaking. I needed to fabricate some additional parts. Old exercise machine to the rescue. This is probably the most use this machine has seen. Lots of cutting and grinding. Lots of whacking. I’m heck at whacking. (see the Harrison Ford film Witness)

The first iteration of the ring worked, but needed tweaking. I needed to fabricate some additional parts. Old exercise machine to the rescue. This is probably the most use this machine has seen. Lots of cutting and grinding. Lots of whacking. I’m heck at whacking. (see the Harrison Ford film Witness) This project was supported by the North Carolina Arts Council, a division of the Department of Natural and Cultural Resources.

This project was supported by the North Carolina Arts Council, a division of the Department of Natural and Cultural Resources.Another Public Sculpture idea model

This project was supported by the North Carolina Arts Council, a division of the Department of Natural and Cultural Resources.

This project was supported by the North Carolina Arts Council, a division of the Department of Natural and Cultural Resources.LivengoodStudio all new deluxe tubing ring roller

Ain’t it always the truth? To build something, you have to build something else first. To build my public sculpture, I need a large ring roller. I have bent the rings for other pieces by hand around a wooden circle. This will not produce consistently sized rings. I need the rings to be a very close match in size for the sculpture to work. Hence a ring roller. It began life as an exercise machine that was used the way most exercise machines are used. Sparingly and then to the Biltmore Steel Recycling yard, then to me. I have a better use for it. Voila, maybe. A ring roller. I have included a picture on a “real” store bought one for reference.

Ain’t it always the truth? To build something, you have to build something else first. To build my public sculpture, I need a large ring roller. I have bent the rings for other pieces by hand around a wooden circle. This will not produce consistently sized rings. I need the rings to be a very close match in size for the sculpture to work. Hence a ring roller. It began life as an exercise machine that was used the way most exercise machines are used. Sparingly and then to the Biltmore Steel Recycling yard, then to me. I have a better use for it. Voila, maybe. A ring roller. I have included a picture on a “real” store bought one for reference. This project was supported by the North Carolina Arts Council, a division of the Department of Natural and Cultural Resources.

This project was supported by the North Carolina Arts Council, a division of the Department of Natural and Cultural Resources.First Maquette of a LivengoodStudio Public Sculpture

Maquette

Maquette

A maquette is a scale model or rough draft of an unfinished sculpture. An equivalent term is bozzetto, from the Italian word for “sketch”. A maquette is used to visualize and test forms and ideas without incurring the expense and effort of producing a full-scale piece. This project was supported by the North Carolina Arts Council, a division of the Department of Natural and Cultural Resources.

This project was supported by the North Carolina Arts Council, a division of the Department of Natural and Cultural Resources.First plasma cut

My welding yard is an roofed shed off the back of my home. I finally got it out on December 30 and tried it out. I had some minor problems and called PrimeWeld. I got someone on the phone right away. They put me in contact with George’s Plasma Cutter And Welder Repair Shop. George walked me through my questions and shazam the plasma torch worked beautifully. The reviews I read about PrimeWeld were true. Great customer service!!

My welding yard is an roofed shed off the back of my home. I finally got it out on December 30 and tried it out. I had some minor problems and called PrimeWeld. I got someone on the phone right away. They put me in contact with George’s Plasma Cutter And Welder Repair Shop. George walked me through my questions and shazam the plasma torch worked beautifully. The reviews I read about PrimeWeld were true. Great customer service!!

I made my first test cut through stainless steel . Now I just need to design a sculpture and build it. What could go wrong? How hard could it be?

I made my first test cut through stainless steel . Now I just need to design a sculpture and build it. What could go wrong? How hard could it be? This project was supported by the North Carolina Arts Council, a division of the Department of Natural and Cultural Resources.

This project was supported by the North Carolina Arts Council, a division of the Department of Natural and Cultural Resources.Artist Support Grant New Equipment Arrival

I received my new Multi-process Primeweld CT520D 50A Plasma Cutter/200A Tig/Stick Welder today. It surprisingly only weighs 32lbs (that’s 14.5 kilos). Some assembly required. Yahoo!!

I received my new Multi-process Primeweld CT520D 50A Plasma Cutter/200A Tig/Stick Welder today. It surprisingly only weighs 32lbs (that’s 14.5 kilos). Some assembly required. Yahoo!!

This project was supported by the North Carolina Arts Council, a division of the Department of Natural and Cultural Resources.

This project was supported by the North Carolina Arts Council, a division of the Department of Natural and Cultural Resources.Artist Support Grants Again

This project was supported by the North Carolina Arts Council, a division of the Department of Natural and Cultural Resources.

This project was supported by the North Carolina Arts Council, a division of the Department of Natural and Cultural Resources.North Carolina Artist Support Grant Continued

“What will it be made out of?”

“How big is it?”

“Where does it go?”

“Steel and stuff.”

“Bigger than a breadbox, smaller than an aircraft carrier.”

“To a good home.”

This project was supported by the North Carolina Arts Council, a division of the Department of Natural and Cultural Resources.

This project was supported by the North Carolina Arts Council, a division of the Department of Natural and Cultural Resources.North Carolina Artist Support Grant

Wow!! Who would have thought? I applied for a North Carolina Artist Support Grant in September. I’ve was notified that I received the grant to make a public art sculpture. O’boy, now what do I do? Pardon my formal dress, I was at a dinner party when I heard.

Wow!! Who would have thought? I applied for a North Carolina Artist Support Grant in September. I’ve was notified that I received the grant to make a public art sculpture. O’boy, now what do I do? Pardon my formal dress, I was at a dinner party when I heard. This project was supported by the North Carolina Arts Council, a division of the Department of Natural and Cultural Resources.

This project was supported by the North Carolina Arts Council, a division of the Department of Natural and Cultural Resources.Fusion of Wood